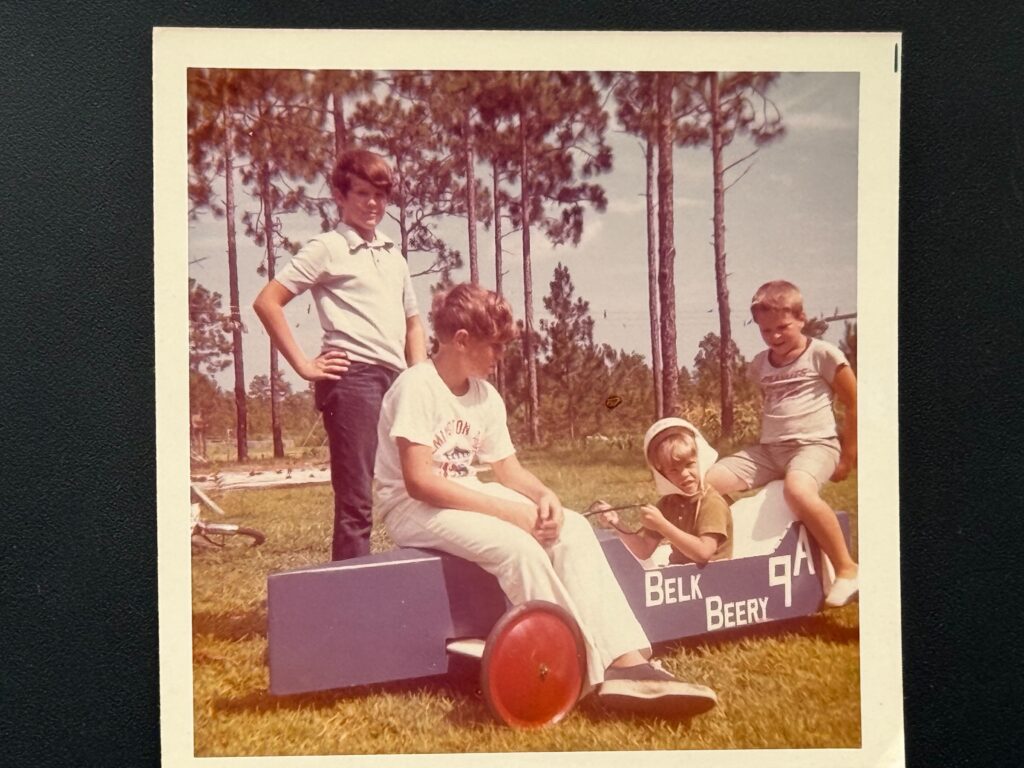

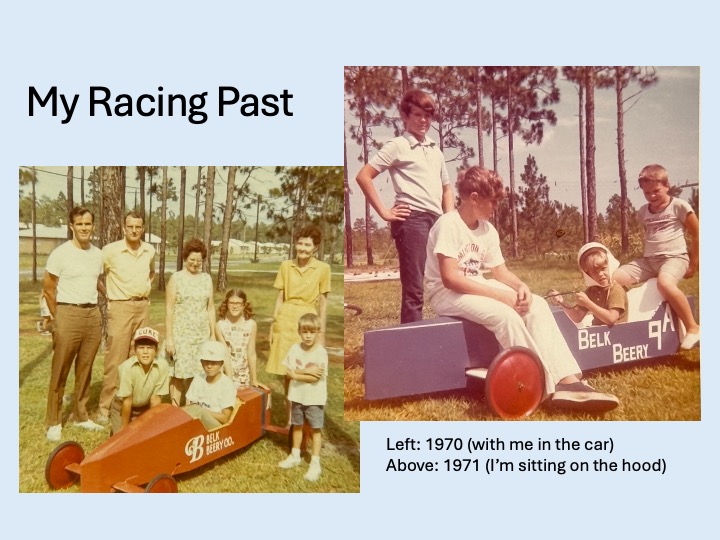

When I was in Wilmington two weeks ago, I spent a lot of time with my sister going through my parents photos and came up with these photos of my soap box derby cars. This is the story of building and racing these cars.

I sat in my car on the starting platform. The platform had been installed at the top of what might be the tallest hill in New Hanover County. They had closed a section of 16th Street for the Saturday running of the 1971 Soap Box Derby. Gripping the wheel and leaning back as far as possible to cut the drag, I glanced over at my opponent. His car was sleek, constructed of fiberglass, but with lots of metal inside. I knew it would be fast, but I had registered good time during the practice trials and had easily won my first race.

The starter, holding high the flag, let it fall. The gates dropped and the cars eased down the plywood ramp and onto the pavement. I concentrated on staying low and keeping my car straight in its lane. The cars began picked up speed. I saw the other car pull slightly ahead as we shot toward the finish line. The checker flag fell. He won and my days of racing had come to an end. Later that morning, the car which beat mine became the overall winner. He got to go to Akron, Ohio, for the nationals.

This was my second year of building a soap box derby. Both years I lost in the second round of a single elimination tournament.

The Wilmington Jaycees held the event. They provided participants with a basic kit which included wheels and axles, a steering wheel, wire, and brake assembly. The sponsors of our event cover the cost and provided a small amount of funds (I think it was $35, which wouldn’t today purchase the plywood) for everything else. I used two sheets. I cut the floorboard and the bulkheads out of ¾ inch plywood. The body I fashioned out of ¼ inch plywood. The metal axles went inside a 1-inch board. Cutting a channel half way through the boards, I chiseled out a channel for the axle. Then I planed down the front side to make the axle cover streamlined.

Those of us who were drivers were to build our own cars with only adult supervision. The first year, I built my car under the carport at our house with David Hunter. David’s father had recently died, so my father served as both of our supervisors. We were to build our cars ourselves, which my father ensured except for the rough cutting of the ¾ inch plywood, which required a circular saw. My father insisted we were too young but allowed us to use jig saws to cut out the bulkheads. Each of these he had us file down to make smooth. I remember lots of stokes using a half-moon file.

The floorboard also had a wooden cutout for a brake. The pedal was made of plywood left over from the center of the bulkheads. A wire ran from pedal to the break in the back, where a wooden 2×4 with a piece of tire on the bottom served as the brake.. When pressed, the brake descended to the road and slowed the car.

Then I attached the bulkheads with angle braces. This was in the day before power drivers, so we drilled pilot holes and used screwdrivers to fix the screws and bolts.

The rear axle and cover were attached with bolts to the back of the floorboard. The front axle was attached with a single bolt, allowing it to move two inches. This was for safety since we were running a straight course. If we could have steered any more, there would probably be cars running into each. This was just enough movement to allow us to make minor adjustments to our path. I then installed the steering wheel between the first two bulkheads in the front. A wire wound around the steering wheel shaft, threaded through pulleys, ran out to each side of the front axle. This allowed us, when racing, to turn the axle slightly to adjust for bumps in the pavement.

At this point, we attached ¼ inch plywood over the bulkheads. The sides were rather simple, but the top required us to use a circular saw with the blade set about 1/8 of an inch to cut strips underneath the plywood, allowing it to bend. With barely any blade showing, my father decided to let us use the saw ourselves.

Once all the plywood was attached, we installed a seat, covered screw holes with putty, and painted the car. My first year, I chose orange with a blue racing strip. For my second year, I used purple with a white stripe. Since we could have a professional do the sponsors lettering on the car, my father volunteered to do it.

When the car was done, we hauled them on a flatbed trailer the day before the race to a warehouse which had been reserved on 13th Street. There, they checked our cars to make sure they weren’t too heavy, and everything was safe and to regulation. My car the first year was about 30 pounds lighter than it had to be. When they checked us in, they kept our cars impounded until race day.

That evening, after the race, the Jaycees threw a banquet for us. We were presented with medals and endured motivation speeches by a couple of the Jaycees.

In building my second car, I mostly worked by myself since David didn’t sign up to build another car. Moving my radio out to the carport, I remember repeatedly hearing that summer Three Dog Night sing “Joy to the World” as I worked.

I had learned a few things from my first car. I wanted the car to be more streamlined and heavier. Trying to figure out how to add weight, my father suggested that instead of buying lightweight angle braces, we use ¼” steel angle iron. Someone he knew cut them into 2-inch-long angles. At the front and back, I used six-inch-long angle iron. This was overkill, but it added weight. Drilling through the iron was difficult, but it was worth it for the weight. I also added more ¾ plywood in the bracing and using solid pieces at the front and back. By the time I completed the car, it was only about 2 pounds under the maximum. The added weight and the sleeker design created a faster car than my first traditional design. In the end, it didn’t matter. The fastest car knocked me out in the second heat.

I love those old photos.

This is so interesting, Jeff! Thanks for sharing your memories and photos! I only saw a soap box derby once in the family housing area of Royal Canadian Air Force Base Greenwood in Nova Scotia when I was 9. It looked like so much fun, and boys and their families were invested in the race like your family was in yours. I was a little envious, because I would have loved to build a car and race like the other kids. Unfortunately, my father wasn’t a “tool” guy, and any tool knowledge I have, I’ve had to figure out myself. My three sisters were smart. They each have skilled “tool guys” as partners. Terry is like my Dad, but Terry has more important qualities which I treasure. I was inspired by Newfies and am very good at inventing tools to solve problems. I thoroughly enjoyed this post, Jeff! You are great at writing memoir! Have a great week!

I wonder if they still have such races and if they do, hopefully girls are allowed to build cars.

Soap box cards are so neat! It must be so much fun to build them.

They were fun but a lot of work.

I was thinking Boy Scouts until I read Ed’s comment. I had to look up Soap Box Derby versus Pinewood Derby to see the difference!

I built Pinewood derby cars, too, but they were mostly carving, sanding, and painting.

Great narrative, Jeff., and I love the pictures. You obviously had a great team (pit crew!) behind you.

I like the idea of having a great pit crew!

What a great experience. I am a Formula 1 fan–those guys start as young kids (not building their own cars, of course, though that would be a great idea).

I had a friend in Savannah whose high school son raced–talk about an expensive hobby!

Soap box cars always sounded fun and I wish we had such things but alas, living on the flat prairie, I only read about them in the newspaper. Instead, we did pine wood derby cars through the boyscouts and just had to imagine we were in the seat as they flew down the track.

But I also remember pinewood derby cars flying off the track (which I wouldn’t want to do in a soapbox derby car.